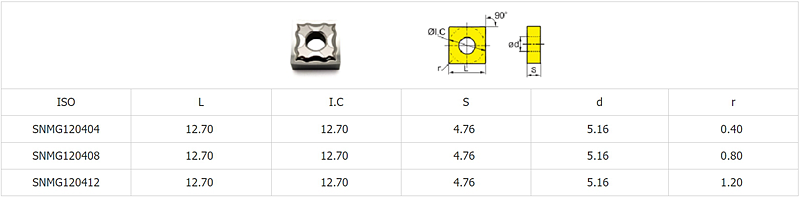

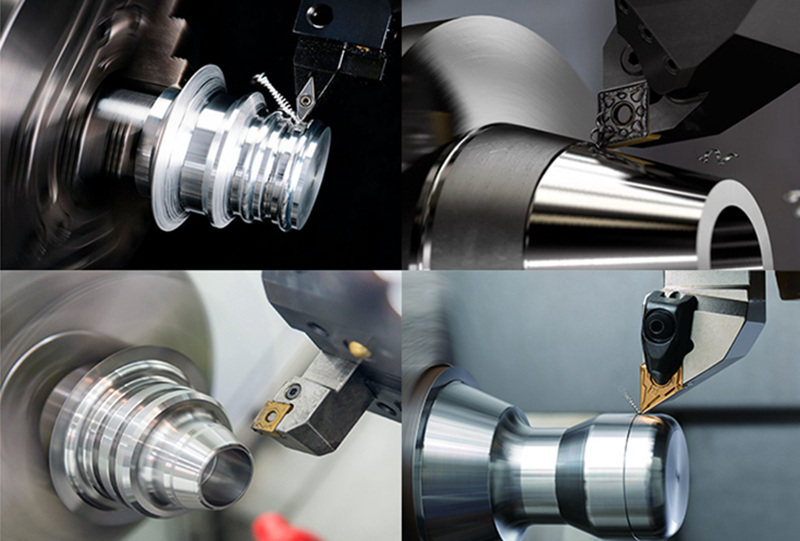

SNMG Insert, with its unique design that helps prevent cratering. You used carbon and alloy steels, stainless steel, and high-temperature alloys. Insert for turning SNMG, square, zero degrees of clearance angle, double-sided, available in several brands and references.

|

Grade

|

신청

|

|

MT1015

|

High wear resistance insert with coating,such as MT-TICN,thick AL2O3 and TIN;Suitable for steel finishing.

|

|

MT1025

|

Blade security good toughness matrix in MT – TICN, thick AL2O3, excellent combination of TIN coating;Is suitable for semi-finishing steel.

|

|

MT1035

|

In the high strength plastic substrate resistance and MT – TICN, thick AL2O3, TIN coating combination;Has good toughness and plasticity deformation, suitable for steel The rough machining.

|

|

MT2015

|

High wear resistance matrix and MT – TI (CN), thick excellent combination, AL2O3, and TIN coating is suitable for finishing and semi-finishing of cast iron materials.

|

|

MT3015

|

pecial organization structure matrix combined with thin TICN, AL2O3, TIN coating, has a good impact resistance and resistance to plastic deformation ability, at the same time Good shock resistance, suitable for the finishing, semi-finishing and roughing of stainless steel.

|

|

MT3025

|

TICN substrate from good toughness and strength, thin, AL2O3, and TIN coating is suitable for semi-finishing and roughing of stainless steel.

|

|

MT3125

|

Stainless steel efficient processing CVD new brands, which are widely used in big cut deep into to efficient processing field.To adopt advanced technology of ultrafine grain nanostructured coating, Gradient alloy substrate with high toughness,excellent performance, in the big cutting depth, feed, high speed cutting process has excellent cuttingperformance.

|

|

MT1215

|

Thick thick TICN and AL2O3 coating, the impact toughness increase at the same time, the wear resistance has increased significantly, is processed to semi-finishing steel high-speed cutting The ideal choice of the cutting.Cutting speed can be increased by more than 25%, under the same cutting speed and tool life can be improved by more than 30%.

|

|

MT1225

|

Adopts thick TICN and AL2O3 coating thick, strong ability to resist plastic deformation and the blade intensity, is closed from finishing to rough machining of steel Choose brand.Under the high removal rate cutting parameters or harsh working conditions has stable performance, and can achieve more green dry cutting.cut Cutting speed can be increased by more than 25%, under the same cutting speed and tool life can be improved by more than 30%.

|

LOWIFAR CNC 도구

LOWIFAR CNC 도구