Drehmaschinen gehören zu den ältesten Zerspanungstechnologien, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

One of the key characteristics of a lathe, unlike a vertical or horizontal milling machine, is that the workpiece turns, as opposed to the tool. Thus, lathe work is often called turning. Drehend, then, is a machining process used to make round, cylindrical parts. Lathes are commonly used to reduce the diameter of a workpiece to a specific dimension, producing a smooth surface finish. Basically, the cutting tool approaches the rotating workpiece until it begins peeling away the surface as it moves linearly across the side (if the part is a shaft) or across the face (if the part is drum-shaped).

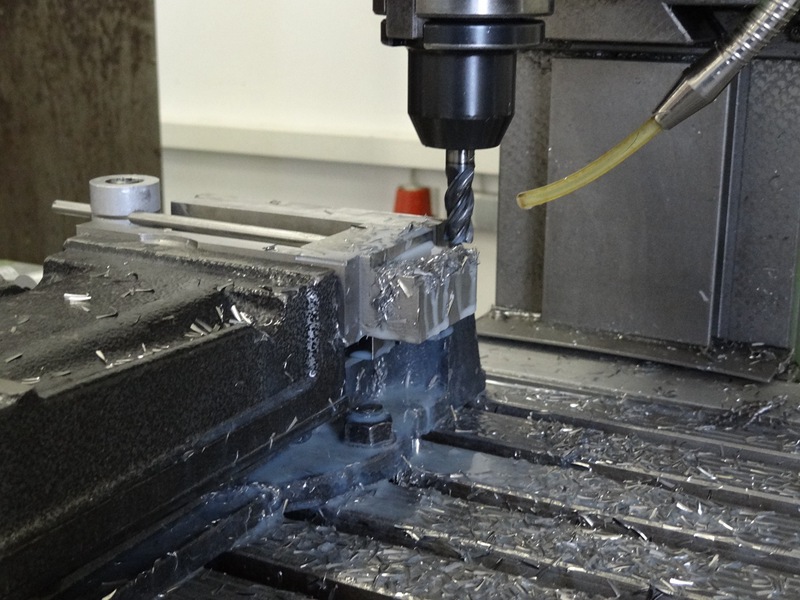

Very few lathes today are not controlled by a CNC, although you can still buy a manually controlled lathe. When equipped with means for changing tools out automatically, such as with a tool turret, the CNC lathe is more properly called a turning center. CNC turning centers are available in a wide range of sizes and capabilities, from simple two-axis lathes, which move in only X and Y, to more sophisticated, multi-axis turning centers capable of handling complex four-axis turning operations, milling, drilling, tapping and deep-hole boring — all in one operation.

LOWIFAR CNC-WERKZEUG

LOWIFAR CNC-WERKZEUG